ą¤ą¤ą„ ą¤øą„ą¤ą¤¾ ą¤¹ą„ ą¤ą¤æ ą¤ą¤¾ą¤°ą„-ą¤ą¤°ą¤ą¤® ą¤ą¤Ŗą¤ą¤°ą¤£ ą¤ą„ą¤øą„

ą¤ą¤ą¤ą„ą¤°ą„ą¤ ą¤®ą¤æą¤ą„ą¤øą¤°

ą¤ą¤° ą¤ą¤Øą¤Ø ą¤ą„ą¤°ą¤¶ą¤° ą¤¦ą¤¶ą¤ą„ą¤ ą¤¤ą¤ ą¤ą¤°ą„ą¤·ą¤£ ą¤øą„ ą¤ą„ą¤øą„ ą¤ą¤æą¤ ą¤Ŗą¤¾ą¤¤ą„ ą¤¹ą„ą¤? ą¤ą¤øą¤ą¤¾ ą¤°ą¤¹ą¤øą„ą¤Æ ą¤ą¤ą¤ą„ą¤Øą¤æą¤Æą¤°ą¤æą¤ą¤ ą¤®ą„ą¤ ą¤ą¤æą¤Ŗą¤¾ ą¤¹ą„

ą¤Ŗą¤¹ą¤Øą¤Øą„ ą¤ą„ ą¤²ą¤æą¤ ą¤Ŗą„ą¤°ą¤¤ą¤æą¤°ą„ą¤§ą„ ą¤®ą¤æą¤¶ą„ą¤° ą¤§ą¤¾ą¤¤ą„ ą¤ą¤¾ą¤øą„ą¤ą¤æą¤ą¤

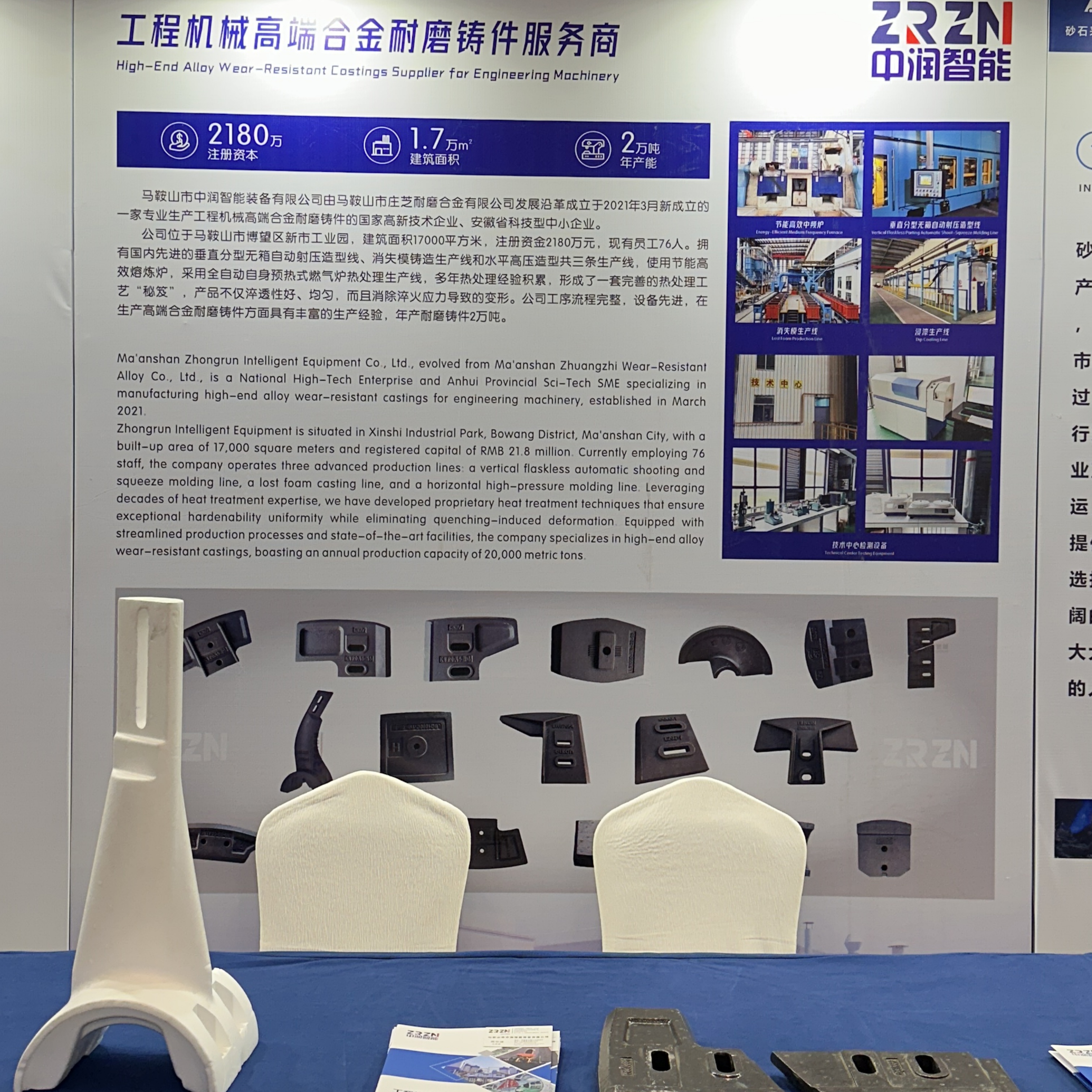

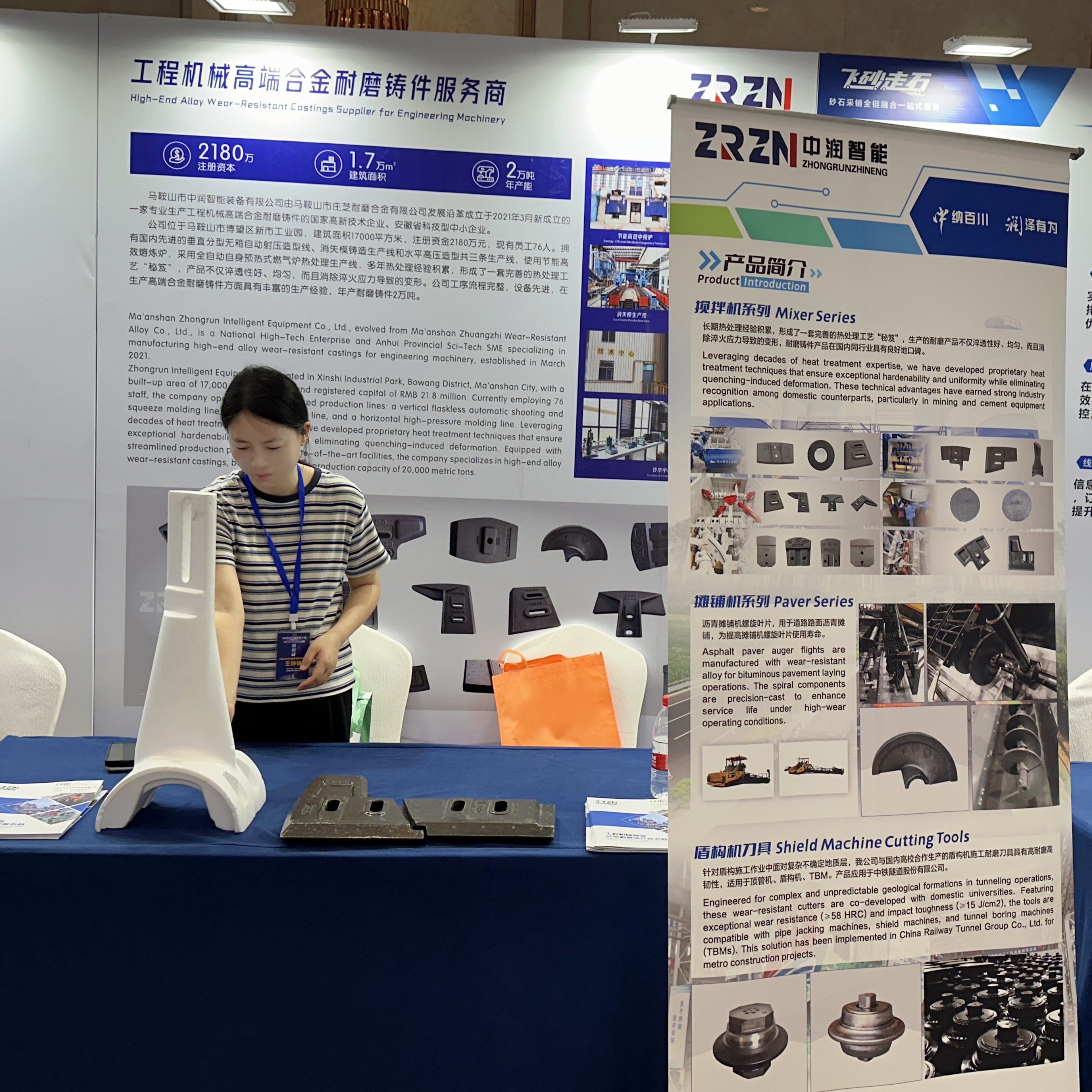

āą¤®ą¤¾ą¤Øą¤¶ą¤¾ą¤Ø ą¤ą„ą¤ą¤ą¤°ą„ą¤Ø ą¤ą¤ą¤ą„ą¤²ą¤æą¤ą„ą¤ą¤ ą¤ą¤ą„ą¤µą¤æą¤Ŗą¤®ą„ą¤ą¤ ą¤ą¤ą¤Ŗą¤Øą„ ą¤²ą¤æą¤®ą¤æą¤ą„ą¤” ą¤ą„ ą¤ą¤ ą¤µą¤æą¤¶ą„ą¤·ą¤¤ą¤¾ą„¤ ą¤ą¤ ą¤°ą¤¾ą¤·ą„ą¤ą„ą¤°ą„ą¤Æ ą¤ą¤ą„ą¤-ą¤¤ą¤ą¤Øą„ą¤ą„ ą¤ą¤¦ą„ą¤Æą¤® ą¤ą„ ą¤°ą„ą¤Ŗ ą¤®ą„ą¤, ą¤¹ą¤® ą¤ą¤øą„ ą¤ą¤¾ą¤øą„ą¤ą¤æą¤ą¤ ą¤”ą¤æą¤ą¤¼ą¤¾ą¤ą¤Ø ą¤ą¤°ą¤¤ą„ ą¤¹ą„ą¤ ą¤ą„ ą¤µą¤æą¤¶ą¤æą¤·ą„ą¤ ą¤¤ą¤¾ą¤Ŗ ą¤ą¤Ŗą¤ą¤¾ą¤° ą¤¤ą¤ą¤Øą„ą¤ą„ą¤ ą¤ą„ ą¤®ą¤¾ą¤§ą„ą¤Æą¤® ą¤øą„ ą¤®ą¤¶ą„ą¤Øą„ą¤ ą¤ą¤¾ ą¤ą„ą¤µą¤Øą¤ą¤¾ą¤² 50%+ ą¤¤ą¤ ą¤¬ą¤¢ą¤¼ą¤¾ ą¤¦ą„ą¤¤ą„ ą¤¹ą„ą¤ą„¤ ą¤Æą„ ą¤Øą¤µą¤¾ą¤ą¤¾ą¤° 2025 ą¤Æą¤¾ą¤ą¤ą„ą¤¤ą„ą¤ą¤¼ą„ ą¤Øą¤¦ą„ ą¤”ą„ą¤²ą„ą¤ą¤¾ ą¤°ą„ą¤¤ ą¤ą¤µą¤ ą¤Ŗą¤¤ą„ą¤„ą¤° ą¤øą¤®ą„ą¤®ą„ą¤²ą¤Ø (10-11 ą¤ą„ą¤²ą¤¾ą¤, ą¤ą¤æą¤Æą¤¾ą¤ą¤ą¤Æą¤æą¤Ø) ą¤®ą„ą¤ ą¤Ŗą„ą¤°ą¤®ą„ą¤ą¤¤ą¤¾ ą¤øą„ ą¤ą¤ą¤°ą„, ą¤ą¤¹ą¤¾ą¤ ą¤¹ą¤®ą¤Øą„ ą¤øą„ą¤„ą¤æą¤°ą¤¤ą¤¾ ą¤øą¤ą¤¬ą¤ą¤§ą„ ą¤ą„ą¤Øą„ą¤¤ą¤æą¤Æą„ą¤ ą¤øą„ ą¤Øą¤æą¤Ŗą¤ą¤Øą„ ą¤ą„ ą¤²ą¤æą¤ ą¤ą¤¦ą„ą¤Æą„ą¤ ą¤ą¤ą¤¤ ą¤ą„ ą¤

ą¤ą„ą¤°ą¤£ą„ ą¤²ą„ą¤ą„ą¤ ą¤ą„ ą¤øą¤¾ą¤„ ą¤øą¤¹ą¤Æą„ą¤ ą¤ą¤æą¤Æą¤¾ą„¤

ą¤µą¤æą¤ą„ą¤ą¤¾ą¤Ø ą¤ą¤° ą¤øą„ą¤„ą¤¾ą¤Æą¤æą¤¤ą„ą¤µ ą¤ą¤¾ ą¤®ą¤æą¤²ą¤Ø: ą¤ą„ą¤ą¤ą¤°ą„ą¤Ø ą¤ą¤¾ ą¤²ą¤¾ą¤

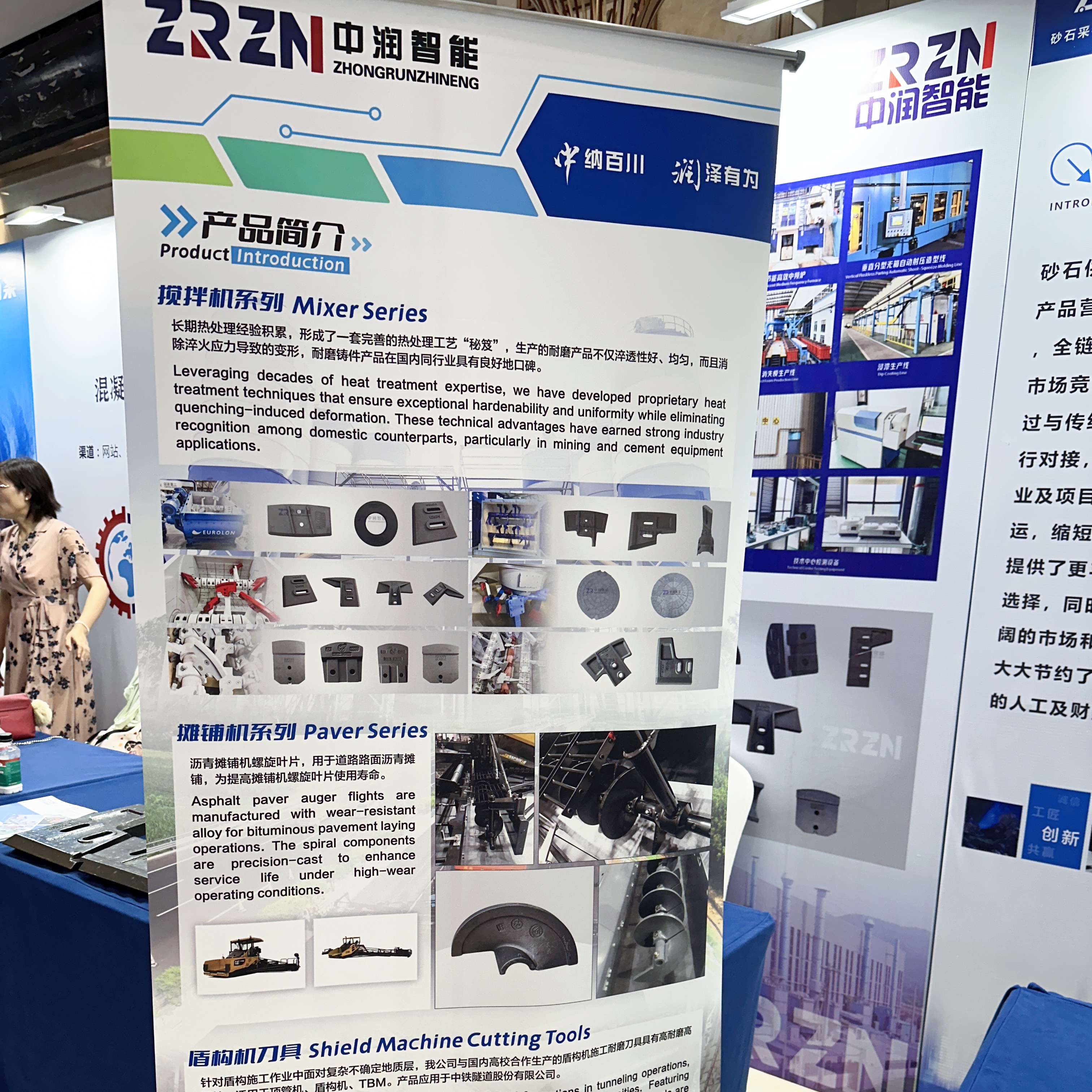

ą¤¹ą¤®ą¤¾ą¤°ą„ ą¤ą¤¾ą¤øą„ą¤ą¤æą¤ą¤ ą¤ą„ą¤°ą„ą¤®ą¤æą¤Æą¤® ą¤ą¤¾ą¤°ą„ą¤¬ą¤¾ą¤ą¤” ą¤®ą¤æą¤¶ą„ą¤°ą¤§ą¤¾ą¤¤ą„ą¤ą¤ ą¤ą¤° ą¤øą„ą¤µą¤ą¤¾ą¤²ą¤æą¤¤ ą¤ą¤¤ą„ą¤Ŗą¤¾ą¤¦ą¤Ø ą¤²ą¤¾ą¤ą¤Øą„ą¤ ą¤ą¤¾ ą¤²ą¤¾ą¤ ą¤ą¤ ą¤¾ą¤¤ą„ ą¤¹ą„ą¤āą¤ą¤æą¤Øą¤®ą„ą¤ ą¤µą¤°ą„ą¤ą¤æą¤ą¤² ą¤«ą„ą¤²ą¤¾ą¤øą„ą¤ą¤²ą„ą¤ø ą¤®ą„ą¤²ą„ą¤”ą¤æą¤ą¤ ą¤ą¤° ą¤²ą„ą¤øą„ą¤ ą¤«ą„ą¤® ą¤ą¤¾ą¤øą„ą¤ą¤æą¤ą¤ ą¤øą¤æą¤øą„ą¤ą¤® ą¤¶ą¤¾ą¤®ą¤æą¤² ą¤¹ą„ą¤āą¤¤ą¤¾ą¤ą¤æ ą¤¬ą„ą¤ą„ą¤”ą¤¼ ą¤ą¤ ą„ą¤°ą¤¤ą¤¾ (54 HRC ą¤¤ą¤) ą¤ą¤° ą¤Ŗą„ą¤°ą¤ą¤¾ą¤µ ą¤Ŗą„ą¤°ą¤¤ą¤æą¤°ą„ą¤§ (15 J/cmĀ²) ą¤Ŗą„ą¤°ą¤¾ą¤Ŗą„ą¤¤ ą¤¹ą„ ą¤øą¤ą„ą„¤ ą¤øą¤¾ą¤®ą¤¾ą¤Øą„ą¤Æ ą¤Ŗą„ą¤°ą„ą¤ą„ą¤ ą¤ą„ ą¤µą¤æą¤Ŗą¤°ą„ą¤¤, ą¤Ŗą„ą¤°ą¤¤ą„ą¤Æą„ą¤ ą¤ą¤ą¤ ą¤øą„ą¤µ-ą¤µą¤æą¤ą¤øą¤æą¤¤ ą¤ą„ą¤ø ą¤ą¤ą„ą¤ą¤æą¤Æą„ą¤ ą¤®ą„ą¤ ą¤

ą¤Øą„ą¤ą„ą¤²ą¤æą¤¤ ą¤¤ą¤¾ą¤Ŗ ą¤ą¤Ŗą¤ą¤¾ą¤° ą¤øą„ ą¤ą„ą¤ą¤°ą¤¤ą¤¾ ą¤¹ą„ą„¤ ą¤Æą¤¹ ą¤øą„ą¤ą„ą¤·ą„ą¤®-ą¤øą¤ą¤°ą¤ą¤Øą¤¾ą¤¤ą„ą¤®ą¤ ą¤ą¤ą¤°ą„ą¤Ŗą¤¤ą¤¾ (ą¤®ą„ą¤ą¤¾ą¤²ą„ą¤ą„ą¤°ą¤¾ą¤«ą¤æą¤ ą¤Ŗą¤°ą„ą¤ą„ą¤·ą¤£ ą¤¦ą„ą¤µą¤¾ą¤°ą¤¾ ą¤øą¤¤ą„ą¤Æą¤¾ą¤Ŗą¤æą¤¤) ą¤øą„ą¤Øą¤æą¤¶ą„ą¤ą¤æą¤¤ ą¤ą¤°ą¤¤ą„ ą¤¹ą„ą¤ ą¤¶ą¤®ą¤Ø ą¤µą¤æą¤°ą„ą¤Ŗą¤£ ą¤ą„ ą¤øą¤®ą¤¾ą¤Ŗą„ą¤¤ ą¤ą¤°ą¤¤ą¤¾ ą¤¹ą„ą„¤ ą¤Ŗą¤°ą¤æą¤£ą¤¾ą¤®?

ą¤ą¤Øą¤Ø ą¤®ą¤¶ą„ą¤Øą¤°ą„

ą¤ą„ą¤°ą¤¶ą¤° ą¤²ą¤¾ą¤ą¤Øą¤° ą¤ą„ą¤øą„ ą¤ą¤ą¤ 30% ą¤

ą¤§ą¤æą¤ ą¤øą¤®ą¤Æ ą¤¤ą¤ ą¤ą¤¾ą¤® ą¤ą¤°ą¤¤ą„ ą¤¹ą„ą¤, ą¤ą¤æą¤øą¤øą„ ą¤Ŗą„ą¤°ą¤¤ą¤æą¤øą„ą¤„ą¤¾ą¤Ŗą¤Ø ą¤²ą¤¾ą¤ą¤¤ ą¤ą¤° ą¤ą¤¦ą¤¾ą¤Ø ą¤”ą¤¾ą¤ą¤Øą¤ą¤¾ą¤ą¤® ą¤ą¤® ą¤¹ą„ ą¤ą¤¾ą¤¤ą¤¾ ą¤¹ą„ą„¤

ą¤ą¤¤ą„ą¤Ŗą¤¾ą¤¦ą„ą¤ ą¤øą„ ą¤Ŗą¤°ą„: ą¤¹ą¤°ą¤æą¤¤ ą¤ą¤µą¤æą¤·ą„ą¤Æ ą¤ą„ ą¤²ą¤æą¤ ą¤øą„ą¤®ą¤¾ą¤°ą„ą¤ ą¤µą¤æą¤Øą¤æą¤°ą„ą¤®ą¤¾ą¤£

ą¤ą¤æą¤Æą¤¾ą¤ą¤ą¤Æą¤æą¤Ø ą¤øą¤®ą„ą¤®ą„ą¤²ą¤Ø ą¤®ą„ą¤, ą¤¹ą¤®ą¤Øą„ ą¤Ŗą„ą¤°ą¤¦ą¤°ą„ą¤¶ą¤æą¤¤ ą¤ą¤æą¤Æą¤¾ ą¤ą¤æ ą¤ą„ą¤øą„ ą¤ą¤ą„ą¤ą„ą¤¤ IoT ą¤Ŗą„ą¤°ą¤£ą¤¾ą¤²ą¤æą¤Æą¤¾ą¤āą¤ą„ą¤øą„ ą¤¹ą¤®ą¤¾ą¤°ą¤¾ ą¤ą¤ą¤ą„ą¤²ą¤æą¤ą„ą¤ą¤ ą¤®ą„ą¤Øą„ą¤Æą„ą¤«ą„ą¤ą„ą¤ą¤°ą¤æą¤ą¤ ą¤ą¤ą¤”ą¤øą„ą¤ą„ą¤°ą¤æą¤Æą¤² ą¤ą¤ą¤ą¤°ą¤Øą„ą¤ ą¤Ŗą„ą¤²ą„ą¤ą¤«ą¤¼ą„ą¤°ą„ą¤®āą¤Ŗą¤æą¤ą¤²ą¤Øą„ ą¤øą„ ą¤²ą„ą¤ą¤° ą¤®ą¤¶ą„ą¤Øą¤æą¤ą¤ ą¤¤ą¤, ą¤µą¤¾ą¤øą„ą¤¤ą¤µą¤æą¤ ą¤øą¤®ą¤Æ ą¤®ą„ą¤ ą¤ą„ą¤£ą¤µą¤¤ą„ą¤¤ą¤¾ ą¤ą„ą¤°ą„ą¤ą¤æą¤ą¤ ą¤ą„ ą¤øą¤ą„ą¤·ą¤® ą¤¬ą¤Øą¤¾ą¤¤ą„ ą¤¹ą„ą¤ą„¤ ą¤Æą¤¹ ą¤¬ą¤ą¤¦-ą¤²ą„ą¤Ŗ ą¤Ŗą„ą¤°ą¤ą„ą¤°ą¤æą¤Æą¤¾ ą¤ą¤°ą„ą¤ą¤¾ ą¤ą¤Ŗą¤Æą„ą¤ ą¤®ą„ą¤ 18% ą¤ą„ ą¤ą¤®ą„ ą¤²ą¤¾ą¤¤ą„ ą¤¹ą„ (*ISO 14001-ą¤Ŗą„ą¤°ą¤®ą¤¾ą¤£ą¤æą¤¤*) ą¤ą¤° ą¤øą¤¾ą¤„ ą¤¹ą„ ą¤¬ą„ą¤ ą¤ą„ą¤°ą„ą¤øą„ą¤¬ą¤æą¤²ą¤æą¤ą„ ą¤ą„ ą¤ą¤¾ą¤°ą¤ą¤ą„ ą¤¦ą„ą¤¤ą„ ą¤¹ą„ą„¤ ą¤°ą„ą¤¤ ą¤ą¤° ą¤ą¤ą„ą¤°ą„ą¤ą„ą¤ ą¤ą¤¤ą„ą¤Ŗą¤¾ą¤¦ą¤ą„ą¤ ą¤ą„ ą¤²ą¤æą¤, ą¤ą¤øą¤ą¤¾ ą¤

ą¤°ą„ą¤„ ą¤¹ą„:

-

20,000 ą¤ą¤Ø ą¤µą¤¾ą¤°ą„ą¤·ą¤æą¤ ą¤ą„ą¤·ą¤®ą¤¤ą¤¾ ą¤ą¤Ŗą„ą¤°ą„ą¤¤ą¤æ ą¤¶ą„ą¤°ą„ą¤ą¤ą¤²ą¤¾ ą¤øą„ą¤„ą¤æą¤°ą¤¤ą¤¾ ą¤øą„ą¤Øą¤æą¤¶ą„ą¤ą¤æą¤¤ ą¤ą¤°ą¤¤ą„ ą¤¹ą„

-

ą¤ą¤øą„ą¤ą¤® ą¤øą¤®ą¤¾ą¤§ą¤¾ą¤Ø

-

ą¤ą„ą¤Ø ą¤ą„ "ą¤øą„ą¤ą„ą¤²+" ą¤ą¤¦ą„ą¤Æą„ą¤ą¤æą¤ ą¤®ą¤¾ą¤Øą¤ą„ą¤ ą¤ą¤¾ ą¤

ą¤Øą„ą¤Ŗą¤¾ą¤²ą¤Ø

ą¤øą¤¹ą¤Æą„ą¤ ą¤øą„ ą¤Ŗą„ą¤°ą¤ą¤¤ą¤æ ą¤ą„ ą¤¬ą¤¢ą¤¼ą¤¾ą¤µą¤¾ ą¤®ą¤æą¤²ą¤¤ą¤¾ ą¤¹ą„: ą¤”ą„ą¤²ą„ą¤ą¤¾ ą¤ą¤¾ą¤°ą„ą¤Æą¤ą„ą¤°ą¤® ą¤øą„ ą¤

ą¤ą¤¤ą¤°ą„ą¤¦ą„ą¤·ą„ą¤ą¤æ

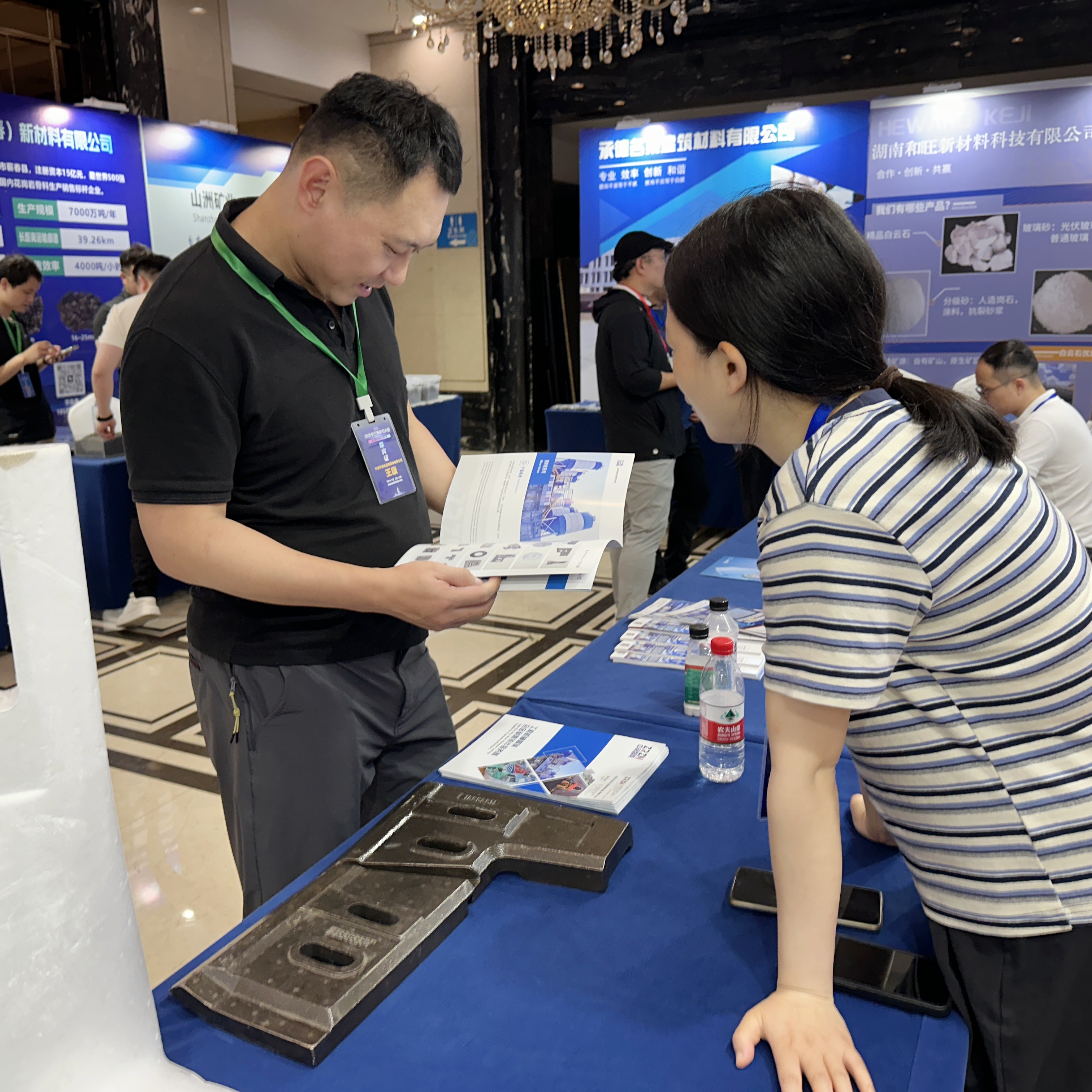

2025 ą¤ą¤¾ ą¤¶ą¤æą¤ą¤° ą¤øą¤®ą„ą¤®ą„ą¤²ą¤Ø ą¤øą¤æą¤°ą„ą¤«ą¤¼ ą¤ą¤ ą¤Ŗą„ą¤°ą¤¦ą¤°ą„ą¤¶ą¤Øą„ ą¤Øą¤¹ą„ą¤ ą¤„ą¤¾āą¤ą¤øą¤Øą„ ą¤ą¤ą¤ą„ą¤°ą„ą¤ ą¤®ą„ą¤²ą„ą¤Æ ą¤¶ą„ą¤°ą„ą¤ą¤ą¤²ą¤¾ ą¤®ą„ą¤ ą¤øą¤¾ą¤ą„ą¤¦ą¤¾ą¤°ą¤æą¤Æą¤¾ą¤ ą¤øą„ą¤„ą¤¾ą¤Ŗą¤æą¤¤ ą¤ą„ą¤ą„¤ ą¤¹ą¤®ą¤Øą„ ą¤ą¤°ą¤® ą¤øą„ą¤„ą¤æą¤¤ą¤æą¤Æą„ą¤ ą¤ą„ ą¤²ą¤æą¤ ą¤®ą¤æą¤¶ą„ą¤° ą¤§ą¤¾ą¤¤ą„ą¤ą¤ ą¤ą„ ą¤øą¤¹-ą¤µą¤æą¤ą¤¾ą¤ø ą¤¹ą„ą¤¤ą„ ą¤øą„ą¤®ą„ą¤ą¤ ą¤ą„ ą¤¦ą¤æą¤ą„ą¤ą¤ ą¤ą¤ą¤Ŗą¤Øą¤æą¤Æą„ą¤ ą¤ą¤° ą¤ą¤Øą¤Ø ą¤ ą„ą¤ą„ą¤¦ą¤¾ą¤°ą„ą¤ ą¤ą„ ą¤øą¤¾ą¤„ ą¤øą¤ą¤Ŗą¤°ą„ą¤ ą¤øą„ą¤„ą¤¾ą¤Ŗą¤æą¤¤ ą¤ą¤æą¤Æą¤¾ą„¤

ą¤Øą¤æą¤·ą„ą¤ą¤°ą„ą¤·: ą¤¬ą„ą¤¦ą„ą¤§ą¤æą¤®ą¤¤ą„ą¤¤ą¤¾ ą¤®ą„ą¤ ą¤Øą¤æą¤µą„ą¤¶ ą¤ą¤°ą„ą¤

ą¤ą„ą¤ą¤ą¤°ą„ą¤Ø ą¤ą„ ą¤ą¤¾ą¤ą„ą¤¦ą¤¾ą¤°ą„ ą¤ą¤ ą¤øą¤ą„ą¤ą¤¾ą¤ ą¤ą„ ą¤°ą„ą¤ą¤¾ą¤ą¤ą¤æą¤¤ ą¤ą¤°ą¤¤ą„ ą¤¹ą„: ą¤ą¤æą¤ą¤¾ą¤ ą¤ą¤¾ą¤øą„ą¤ą¤æą¤ą¤ ą¤øą¤æą¤°ą„ą¤«ą¤¼ ą¤Ŗą„ą¤°ą„ą¤ą„ ą¤Øą¤¹ą„ą¤ ą¤¹ą„ą¤āą¤µą„ ą¤¦ą¤ą„ą¤·ą¤¤ą¤¾ ą¤¬ą¤¢ą¤¼ą¤¾ą¤Øą„ ą¤µą¤¾ą¤²ą„ ą¤ą¤¾ą¤°ą¤ ą¤¹ą„ą¤ą„¤ ą¤ą¤® TCO (ą¤øą„ą¤µą¤¾ą¤®ą¤æą¤¤ą„ą¤µ ą¤ą„ ą¤ą„ą¤² ą¤²ą¤¾ą¤ą¤¤) ą¤ą¤¾ą¤¹ą¤Øą„ ą¤µą¤¾ą¤²ą„ ą¤ą¤Ŗą¤°ą„ą¤ą¤°ą„ą¤ ą¤ą„ ą¤²ą¤æą¤, ą¤Øą¤æą¤®ą„ą¤Øą¤²ą¤æą¤ą¤æą¤¤ ą¤ą¤¾ą¤ą„ą¤¦ą¤¾ą¤°ą„ą¤ ą¤ą„ ą¤Ŗą„ą¤°ą¤¾ą¤„ą¤®ą¤æą¤ą¤¤ą¤¾ ą¤¦ą„ą¤:

1. ą¤ą¤ą¤ą¤øą¤ 9001/45001 ą¤Ŗą„ą¤°ą¤®ą¤¾ą¤£ą¤Ŗą¤¤ą„ą¤°

2. ą¤

ą¤Øą„ą¤øą¤ą¤§ą¤¾ą¤Ø ą¤ą¤µą¤ ą¤µą¤æą¤ą¤¾ą¤ø ą¤ą¤ ą¤¬ą¤ą¤§ą¤Ø

3. ą¤øą¤æą¤¦ą„ą¤§ ą¤ą„ą¤·ą„ą¤¤ą„ą¤° ą¤Ŗą¤°ą¤æą¤£ą¤¾ą¤®

ą¤ą„ą¤Æą¤¾ ą¤ą¤Ŗ ą¤

ą¤Ŗą¤Øą„ ą¤®ą¤¶ą„ą¤Øą¤°ą„ ą¤ą„ ą¤ą¤µą¤æą¤·ą„ą¤Æ ą¤ą„ ą¤²ą¤æą¤ ą¤¤ą„ą¤Æą¤¾ą¤° ą¤ą¤°ą¤Øą„ ą¤ą„ ą¤²ą¤æą¤ ą¤¤ą„ą¤Æą¤¾ą¤° ą¤¹ą„ą¤?

ą¤¹ą¤®ą¤¾ą¤°ą„ ą¤øą¤®ą¤¾ą¤§ą¤¾ą¤Ø ą¤¦ą„ą¤ą„ą¤ ā